It’s an unfortunate fact of life that mistakes happen on the jobsite, and mistakes have consequences. It’s also true that some people attempt to cover up their mistakes rather than fixing them, which may alleviate stress in the moment but can lead to much larger issues and damage down the road.

As a craftsman, it is paramount that you care about the work that was done to the wall prior to you getting on the job, not only on account of your professional pride but also because you could be held liable for anything that has been done incorrectly in the past. For masons and other installers of manufactured stone products, this is why it’s important to complete a thorough wall review process before you begin any work.

Pre-Work Checklist

As a crucial first step, here is a pre-work checklist you can use to evaluate a wall and decide whether or not to alert the General Contractor or owner of a problem before you start any work on a new project:

- Start with an evaluation of the framing skill level:

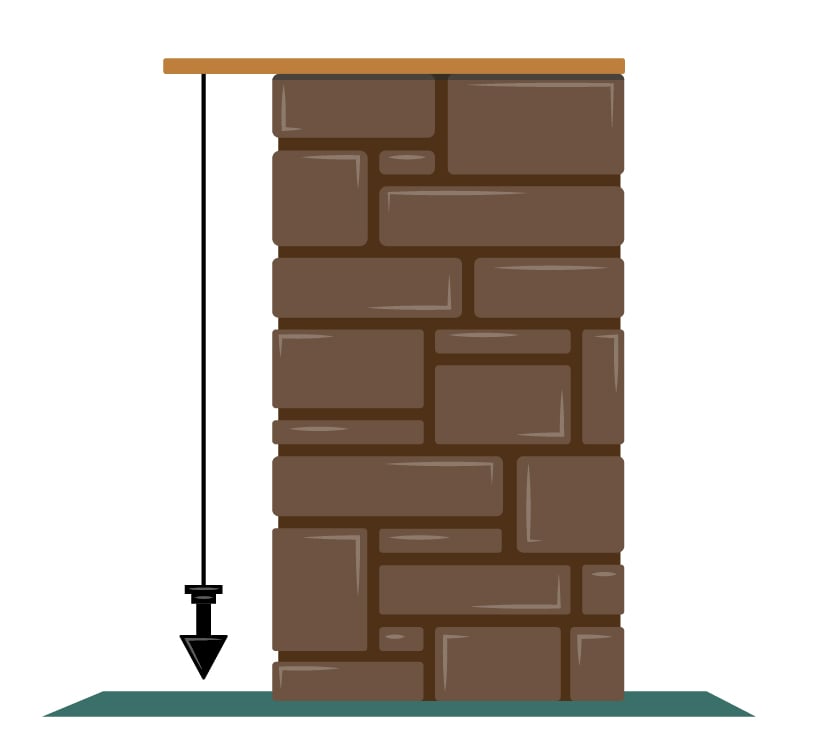

- Is the wall plumb within ¼”?

- Are corners square within a degree or two?

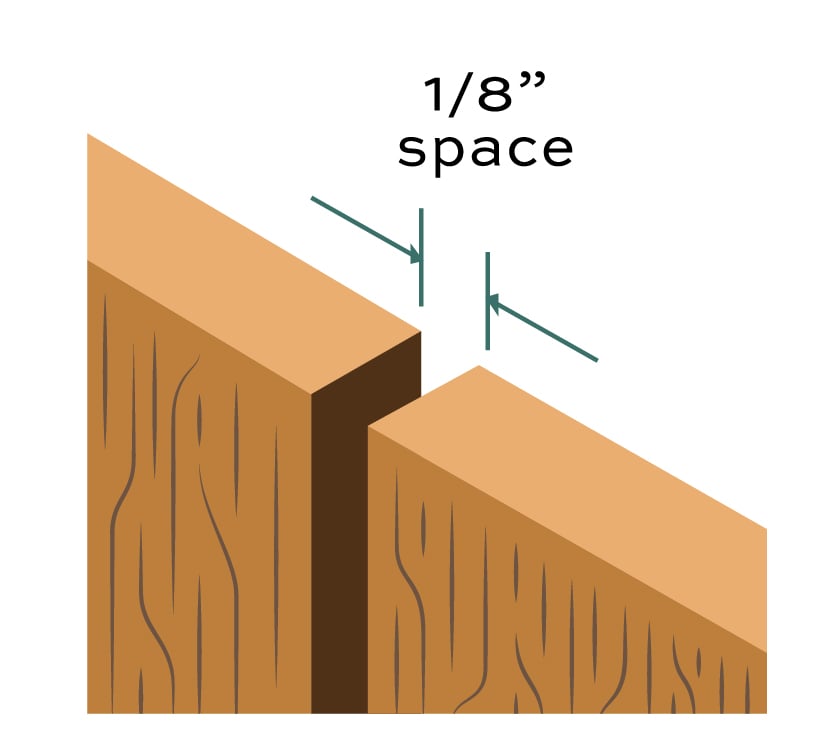

- Has sheathing been properly gapped? Failure to provide that 1/8” gap between sheets can cause cracking later when sheathing expands and has nowhere to go.

- Is the wall plumb within ¼”?

- Next, let’s look over the primary drainage plane:

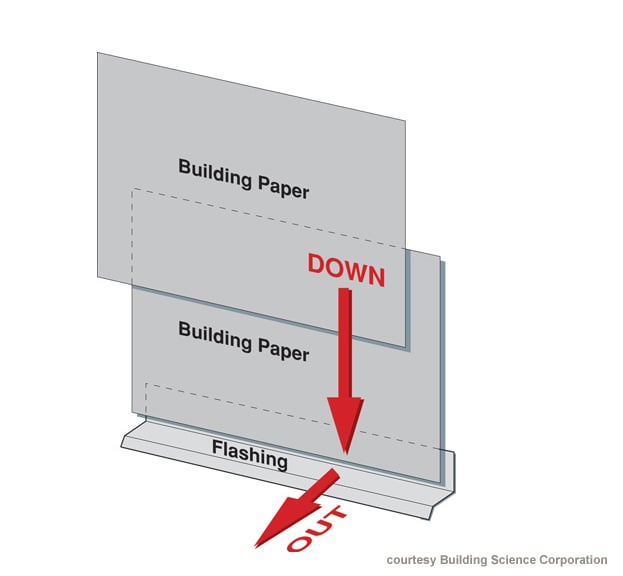

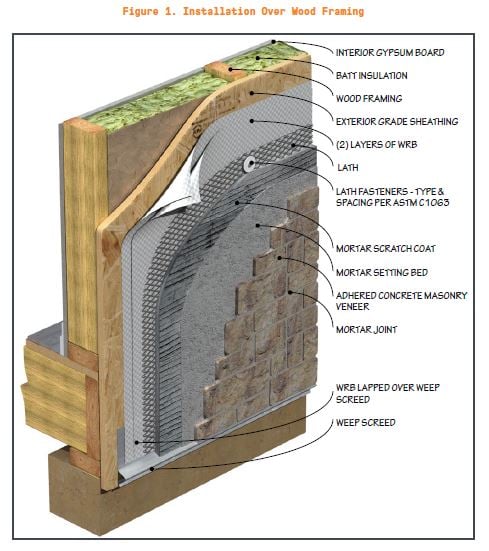

- Is the first layer of Water Resistive Barrier (WRB) installed, lapped correctly and integrated with flashing?

- Are all layers in shingle flashing?

- Are there any tears or damage to the WRB that needs to be repaired? o How long has the WRB been exposed? Most manufacturers have stated limits on exposure. If the WRB has been exposed to UV too long, you need to alert the owner.

- Do windows have head flashings, and are horizontal/vertical cladding terminations and transitions flashed?

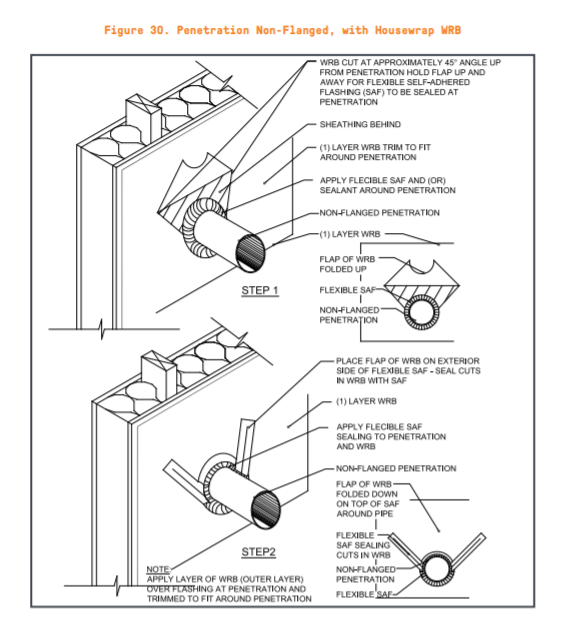

- Are penetrations for mechanical systems flashed?

- Who’s doing the flashing in the first place?

- This question is almost as important as who’s doing the stone work. If you are responsible for flashing, take ownership and follow tested details produced by NCMA and the WRB manufacturer.

- Take time to verify any flashing or air sealing tape you use is compatible with the WRB product. If you are not responsible, go on record as such, but still evaluate the flashing done by others.

- If you find something that doesn’t look like your NCMA details, you need to disclose this to the owner.

- This question is almost as important as who’s doing the stone work. If you are responsible for flashing, take ownership and follow tested details produced by NCMA and the WRB manufacturer.

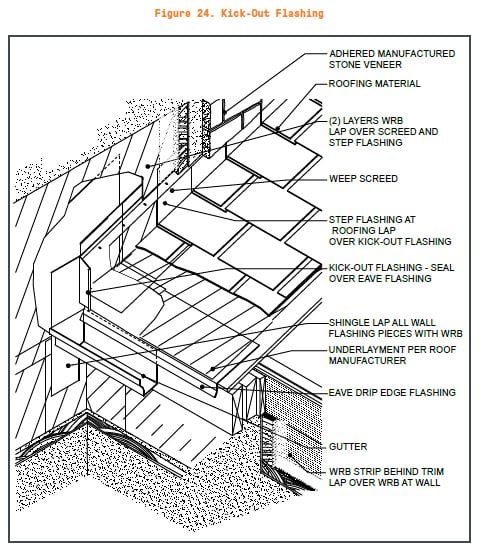

- This is a great time to look at adjacent cladding and roofing systems for proper flashing where they intersect with the stone installation:

- Is a kickout flashing in place? Roof runoff water can flood your new stone installation to the point of failure, so take time now to point this out to your customer.

- Are interior trades, like wallboard, or exterior, like roofing, all done? Adding these products during or after your stone install can lead to movement and increased crack risk.

- Is a kickout flashing in place? Roof runoff water can flood your new stone installation to the point of failure, so take time now to point this out to your customer.

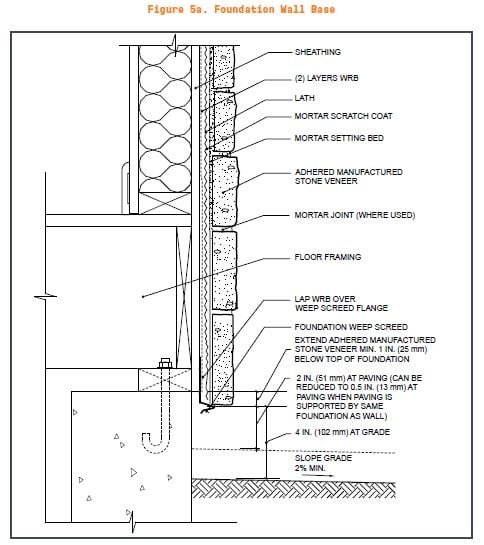

- Lastly, this is a great time to discuss the stone termination at grade:

Share Your Evaluation

With your pre-work checklist completed, you can better determine if the job is ready for you, or if you need to reach out to the owner to make corrections first. Going through these steps confirms to your customers that you are a true craftsman who can be trusted with the project at hand and any future work. Incorporating a pre-work checklist into your job evaluation process provides a professional precedent for your customers. If used frequently, not only will your regular customers become accustomed to the process, but you might also find that future jobs are more readily prepared for you to start once you arrive.

Additional Resources

If you would like to learn more about drainage planes and water management, there are many resources available. Here’s a link to get you started:

Learn more about manufactured stone veneer installation and preparation:

-------

About Technically Speaking

Technically Speaking is a digital education series that is designed to help masons, general contractors, installers and other trade professionals see to their own continuing education. With individual topics and articles moderated by longtime practitioners and industry leaders Jeff Tew and Chris Hines, the series will tackle a variety of subjects, protocols, products and practices. In short, anything and everything pertaining to the manufactured stone veneer (MSV) industry is up for discussion.

Related Categories

Technically SpeakingChris Hines

As the Dev Tech Leader, Chris Hines brings 28 years of experience in the world of building materials, 17 of which have been spent in Manufactured Stone Veneer. Along with his experience, he has extensive knowledge with insulation products, roofing products, foam, windows and even some fence, deck and rail. As the Chair of the NCMA-MSV Technical committee and an active contributing member at ASTM C15, his specialty lies in the technical world of product testing, building codes and standards development. In his role, Chris is a resource to all trade professionals while bringing knowledge and experience in the product development and product management space.

Let Us Know What You Thought about this Post.

Put your Comment Below.